Excitement About Caster Manufacturer

Table of ContentsExcitement About Caster ManufacturerCaster Manufacturer for DummiesThe Only Guide to Caster ManufacturerCaster Manufacturer for BeginnersSome Known Facts About Caster Manufacturer.

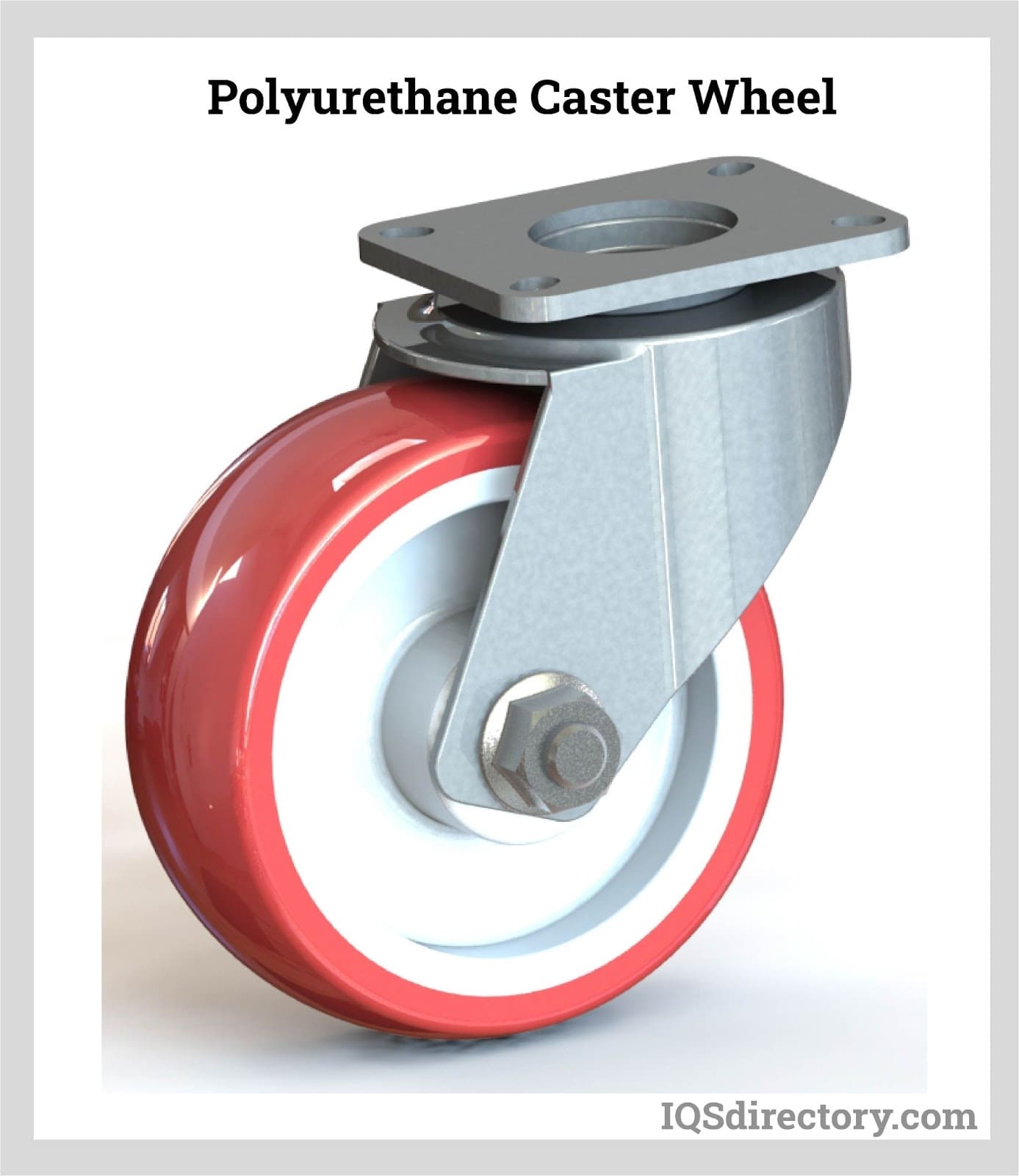

Wheel wheels are made use of in shopping carts, office chairs, medical beds, as well as product handling tools. Caster wheel variations vary greatly based on the application requirements and are commonly utilized in a variety of applications. It is a fantastic wheelchair enabler, with residential properties such as toughness, deterioration resistance, water resistance, and also weather resistance.

Hefty things need casters with thicker wheels, some bigger things could require several wheels to uniformly distribute weight. This section will certainly discuss the manufacturing processes involved in making caster wheels.

Plasma cutting is a sort of thermal reducing that makes use of an ionized gas to cut the metal. This implies that the procedure utilizes heat to thaw the steel as opposed to mechanically reducing it. It is just one of one of the most typical methods for cutting thick steel plates, however it's likewise useful for sheet steel.

Forks are the arms that hold each side of the wheel axle. The forks are made out of steel coil, an extra versatile and thinner type of steel.

10 Simple Techniques For Caster Manufacturer

The press bends the piece right into the called for form and also it likewise makes a circular groove around the hole in the center. The opening is loaded with steel round bearings that allow the yoke to pivot - Caster Manufacturer. A steel retainer is fitted to hold the round bearings in position. The grooves of the steel cap are filled with sphere bearings as well then they position it onto a strike press as well as place the yoke on top.

The following machining process on the manufacturing of caster wheels is the extrusion of the wheel material. To make the wheels, nylon inserts are needed.

The rubber side absorbs shock, lowers noise, and also avoids damage to the flooring or surface area. For larger sized wheels, a various molding press is utilized to suit the required dimension. The molding procedure to create the wheel coincides. These bigger molding press machines generally make one wheel each time.

The steel guides place the wheel between the yokes and place the steel wheel axle. A screw head safeguards one end and a nut is connected to the various other end. Oil is injected to oil the ball bearings. The wheel has to undertake a collection of quality assurance examinations that count the variety of revolutions a caster can withstand prior to it finally damages.

Caster Manufacturer for Beginners

A swivel caster, on the various other hand, may be a better choice if there's demand for more maneuverability. Take into consideration also whether there's need for swivel locks, if devices is to be relocated in a straight line - Caster Manufacturer. The ability to move something is why casters are placed on it, however there's additionally need to know just how much flexibility there is in that movement.

Several applications need a stem placed wheel, although this can limit the wheel's weight ability. Durable wheels will make use of a plate install to safeguard the caster and spread the tons over a better installing location. Recognizing the mounting preference can aid limit the choices when selecting casters from a big number.

This inquiry will certainly help examine if there's a demand for light-duty, medium-duty, or sturdy casters based on the general weight that will certainly be put on them. Wheel wheels differ varying with applications that are from medical, industrial, furniture casters, etc.

They are chemical, oil, as well as acid immune since they are composed of polycarbonate as well as mold-on rubber. While a soft step enables wheels to surrender small debris and also is normally quieter than various other materials, it additionally makes it a lot more hard to roll as Continued well as reduces the caster's overall lots capacity. Polycarbonate rubber, rubber tread on iron core, and also polyurethane tread on plastic core are all typical soft step caster wheels.

The Of Caster Manufacturer

They are additionally used in food solution equipment, processing plants, and other light to tool lots. Ferrous wheels offer the greatest tons ability, influence resistance, temperature array, and rollability of any caster wheel readily available due to the solid framework it has. Ferrous wheels, as the name suggests, are made of built steel or cast iron, making it exceptional for rough situations such as stockrooms and making factories where flooring protection is not a priority.

Strong urethane wheels are one technique to stop these problems. The concern of tread splitting up and core corrosion is minimized due to the fact that the whole wheel is made from molded urethane without core. Artificial wheels with a harder walk have a lower rolling resistance and also a greater effect strength and also integrity.

While a lot of artificial look at more info wheels are ideal for high-impact and also rough scenarios, they are louder than softer materials and are much less forgiving when ramming debris. Phenolic wheels, which are constructed from phenolic material and macerated canvas, are a constant option for push pull applications. Phenolic wheels are solid and also withstand grease and also various other chemicals, making flexibility less complicated.

Gray iron is utilized to make cast iron wheels. Some of the specifications found on this caster wheel consist of solidity of 90-95A; Brinell 145.

The smart Trick of Caster Manufacturer That Nobody is Talking About

These wheels have a solidity of 130 150 brinell. Flanged wheel wheels can operate within a temperature of 800F provided it has proper bearings and lubrication.

The strong wheels are solid in normal usage, can endure high temperatures, and also absorb shock as well as influence without failing. Built steel wheels outshine pliable steel wheels in terms of load capability, influence toughness, and rollability of all wheel wheels. Built steel caster wheels can be operated on concrete and also smooth steel surface areas.

Bearings that can be utilized include plain, address tapered, Teflon, and roller bearings. These caster wheels can operate under the exact same problems which are light chemicals, oily and greasy locations, as well as steel chips on the surface area. These wheels are composed of a nylon and glass mix and also are crafted to stand up to severe temperatures.